Their power to manage a multitude of functions and supplies makes them indispensable in modern day manufacturing.

The piece or perhaps the machine is usually incorrectly placed, causing a crash in which the tools break. Incorrect code or other aspects can add.

Reaming: Reaming good-tunes the scale of drilled holes, featuring a higher degree of precision than drilling alone.

This system assures a cleanse and successful Doing work ecosystem, contributing towards the machine’s longevity and functionality.

The term “machine” generally refers to any equipment that performs get the job done, while a “machining center” is a selected sort of CNC machine Software designed to complete various machining operations.

Watch Okuma’s webcasts to develop your expertise on various manufacturing-associated topics through the lens of Okuma’s machine tools and systems.

Each Haas VMC offers the characteristics and general performance you will need at the best cost, making it the most beneficial financial commitment you’ve ever deemed – providing utility, flexibility, productiveness, and value.

Machining centers during the professional medical industry are vital for manufacturing various equipment and equipment. From surgical instruments to prosthetics and implants, the high precision offered by these centers makes sure client security and effectiveness in medical treatment plans.

Pc Numerical Management machines in its place use Pc plans, prepared in alphanumeric details, with detailed coded instructions for movement and manufacturing method.

The method, identified as turning, is perfect for symmetrical areas, and while it is a lot more confined in terms of the number of axes, lathes are specific and exact, and usually made use of to generate shafts and gears.

A five-axis UMC, for instance, moves the cutting Resource together X, Y, and Z linear axes whilst rotating about the A and B axes. This brings about Outstanding precision when crafting parts like aerospace parts or sophisticated molds.

Based on these customized Recommendations within the G-code file, the machine might be programmed for correct speeds, positions, and can switch out tools for different aspects of the procedure to obtain the greatest final results.

Ahead of CNC existed, there was only NC. What this means is Numerical Control (with no “C” of Pc), the place again in the nineteen fifties punched tape was used to manually input instructions on to info playing cards to describe in which to maneuver the machine and tools to chop sections. This was significantly slower, much less effective, and a lot more susceptible to human error.

The Instrument changer holds different tools get more info which might be speedily swapped out according to the precise demands of the job at hand.

Jennifer Grey Then & Now!

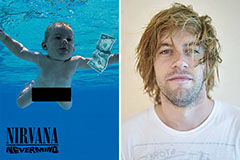

Jennifer Grey Then & Now! Spencer Elden Then & Now!

Spencer Elden Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now!